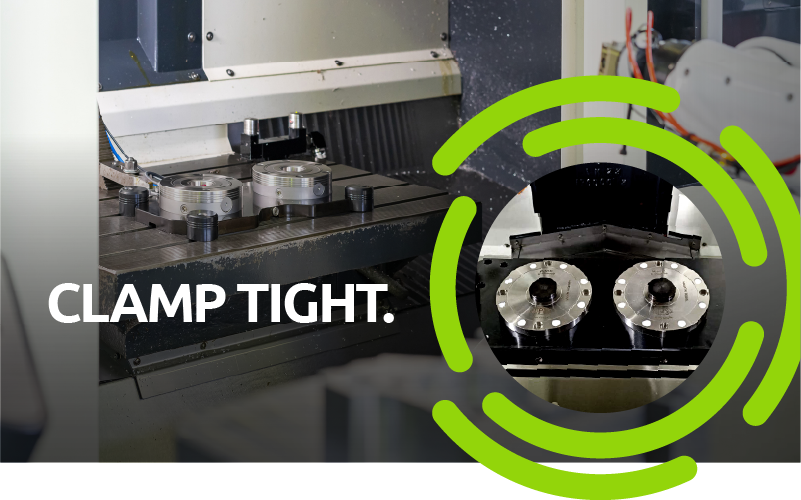

Zero Point Locator

A Zero Point Locator System is a device used to improve the positioning accuracy of machine tools. It can automatically set the machine’s zero point position, reducing human error and enhancing machining precision and efficiency. It is suitable for CNC machines and machining centers.

The system is suitable for milling machines, including traditional milling machines and CNC milling machines. For special requirements, please feel free to contact us.

This system improves machining accuracy and efficiency, reduces human error, shortens setup time, and enhances repeat positioning accuracy, making the machining process more stable.

It is recommended to regularly clean the locator and the machine tool’s worktable, and perform an inspection every three months to ensure proper operation. If any abnormalities occur, please contact us for repair.

Yes, the Zero Point Locator System can automatically adjust the machine’s zero point and perform fine-tuning, ensuring that each machining process returns accurately to the original position, thereby improving machining accuracy and efficiency.

65 type, 100 type, 130 type

65 type: 250 kgf、100 type: 600 kgf、130 type: 600 kgf

The fixture sub-plate contact surface

Made of stainless steel with a hardness of HRC57°.

Over 300,000 cycles.

Repeatability ≤ 0.005 mm.

Our Zero Point Locator System comes with a one-year warranty. During this period, if there are any quality issues with the zero point, you are entitled to free repair or replacement services. Our customer service team will provide full support to ensure the long-term stable operation of your equipment.

It is pneumatically operated.

Minimum air supply pressure: 6 bar.

No.